Our History

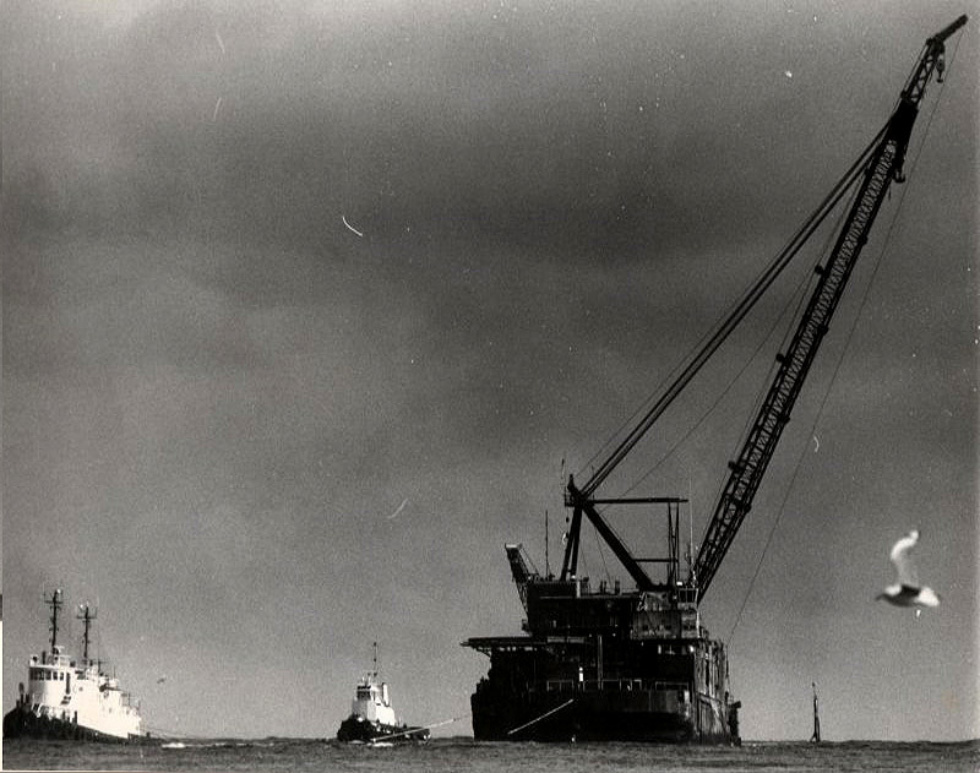

D.B 21 Ray J McDermott

The 10000 ton DB21, Derrick Barge 21 or Dumb Barge 21 (which means that it doesn’t have any form of propulsion), was moored at a specially built berth at Bell Bay. The P.L.A won the contract over considerable odds. One of the main reasons that they secured the work was because of the highly skilled work force that they had at their disposal at this time. One of the more interesting jobs involved repairing a massive rip in the hull of the barge that continued 10 ft. below the water line. For this task to be undertaken a cofferdam was constructed from steel and braced into position. An air hose was then fitted into a channel that ran around the face of the cofferdam and inflated. This acted as a seal so that water could be pumped out and work started. Once the water was removed from inside the cofferdam, water pressure from outside kept it against the hull of the vessel. With men working inside the cofferdam , the 5/8 thick plates were successfully cut out and replaced below the water line with a 2 inch thick doubling plate installed for protection against the massive anchors that secure the barge when working at sea. The machine shop carried out all the survey work required on the three tugs. This involved removing rudders, propellers, propeller shafts, checking bearings and reconditioning sea valves. As well as the repair work, an office and accommodation block were built under the helicopter pad, the communications tower was upgraded, a cinema was installed for the crew and the pipe laying equipment was resized to suit larger diameter pipes being laid at sea.

140 men in total worked on this project, Glasgow Engineering had ten men working full time for the three months on DB21. The company purchased a mini bus for the men to travel to Bell Bay every day for work.