Our History

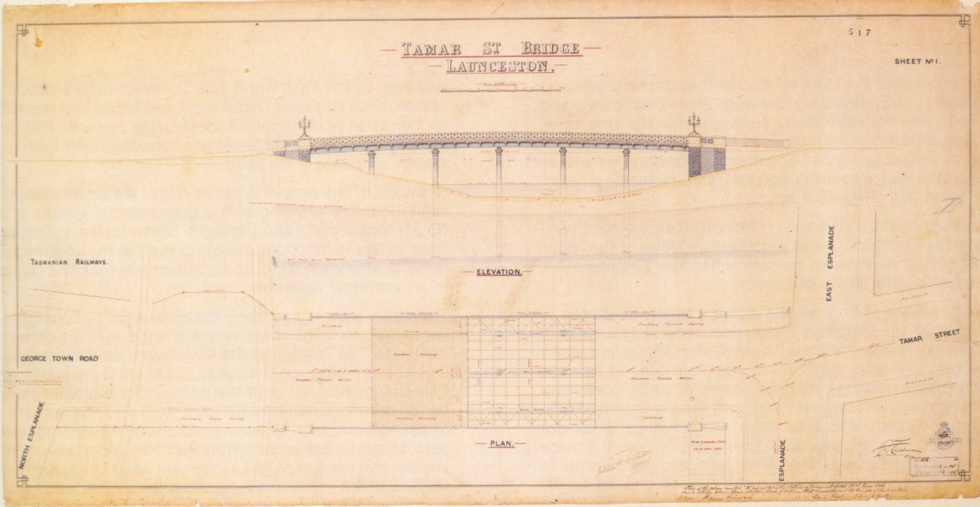

The Victoria Bridge

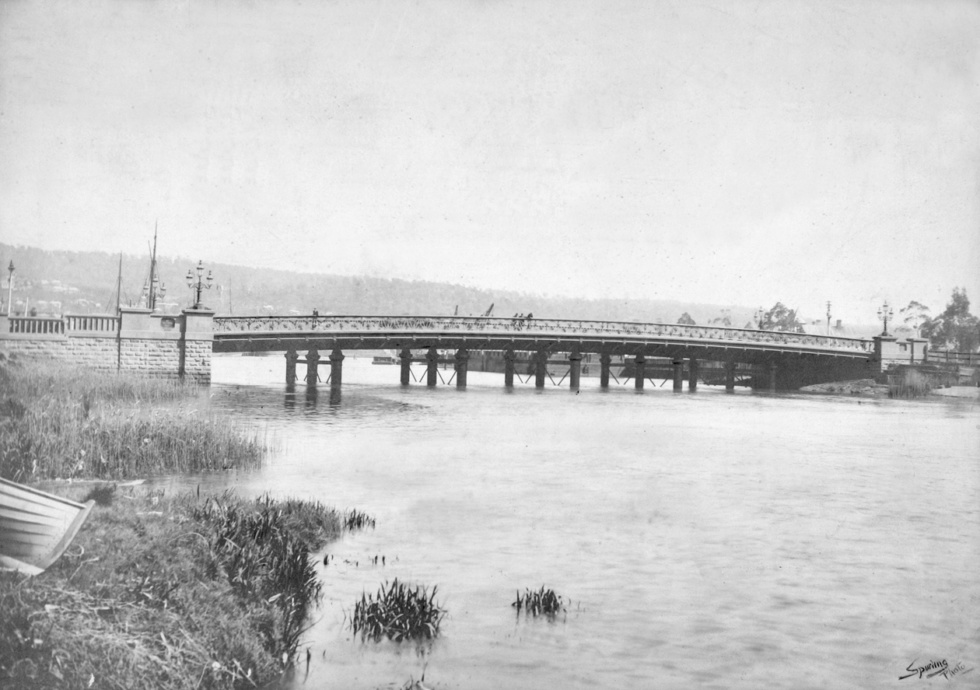

June 1896, Bogle & Clark were awarded the contract to manufacture the Victoria Bridge over the North Esk River in Launceston. This took two years to complete and the price was £10,600. The Bridge was officially opened on the January 10 1899. Only the raw materials were imported, as plates and pig iron, the whole of the casting and girders being made at the firm’s works. Pylons were manufactured with a thread or worm on one end and were screwed through the mud and down to the bed rock using a ratchet system and horses. Each of the pylons were then tested with a 100 ton weight being placed upon them. Between fifty and sixty men were employed during its construction. At the opening Alfred Blades ‘the well-known diver’ performed a somersault from the bridge into the river.

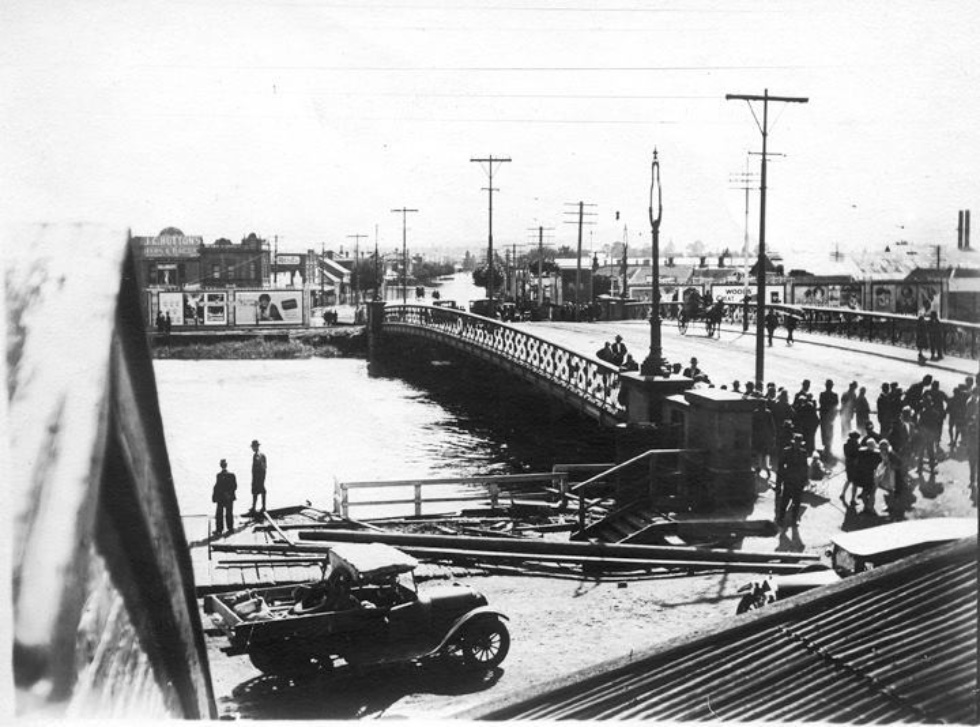

The next time that a large crowd was to assemble on the bridge was on 11th December, 1901. The Victoria Bridge was packed with thousands of people welcoming home the soldiers of the First Tasmanian Contingent returning home from the Boer War in South Africa. The First Tasmanian Contingent was an infantry company raised in October 1899 shortly after the start of the Boer War. The infantry company was established with four officers, one warrant officer, five sergeants, four corporals, two buglers, and 64 privates. Many of the men came from the local Tasmanian colonial forces. They left Launceston on 27 October 1899 arrived at Cape Town on 26 November. The First Tasmanian Contingent was an infantry company raised in October 1899 shortly after the start of the Boer War. The infantry company was established with four officers, one warrant officer, five sergeants, four corporals, two buglers, and 64 privates. Many of the men came from the local Tasmanian colonial forces. They left Launceston on 27 October 1899 arrived at Cape Town on 26 November.

Upon arriving in South Africa the company joined the Australian Regiment, and garrisoned Enslin and other areas protecting the railway. At Naauwpoort, Cape Colony, at the start of February, the company became a mounted unit and joined General Clement’s force. They were engaged in operations around Colesberg, which was occupied on 28 February. The Tasmanians served with the Australian Brigade until April, when the brigade was broken up. They then joined the 1st and 2nd Victorian Mounted Rifles, and the 1st South Australian Mounted Rifles, as part of the 4th Mount Infantry Corps, at Bloemfontein, under the command of Colonel Henry.

The corps patrolled around Bloemfontein and the Tasmanians went into action at Hout Nek on 30 April. The advance to Pretoria began on 2 May and during the advance the mounted infantry corps rode out in front, as part of the screening force, in the centre and centre-left of the column. The riding was hard and they often covered 40 to 50 miles a day. The mounted infantry took part in a number of skirmishes and engagements, notably at Vet River on 6 May and Zand River, where Cameron was wounded on 10 May. After the occupation of Pretoria, the mounted infantry was stationed on the eastern front, participating in the battle of Diamond Hill and the actions at Balmoral at the end of July, and Belfast on 7 September. After “some very hard marching over rough country” Komati Poort was occupied on 24 September. The Tasmanians thus participated in the operations around Colesberg, and took part in the advance from Bloemfontein to Pretoria, including the actions at Karee Kloof, Brandfort, Vet River, Zand River, Elandsfontein, Johannesburg, and Diamond River. They were then part of the advance from Pretoria to Komati Poort, including the actions at Belfast and the occupation of Kapsche Hoop.

The first Tasmanian contingent left Cape Town on the transport Harlech Castle on 3 November 1900 and reached Tasmania on 7 December only 4 were killed or died of wounds and 5 died of disease 7 .

An interesting excerpt from the Examiner which gives a fantastic insight to foundry life in Launceston at the time Tuesday August 17 1897:

BUILDING A BRIDGE: A LARGE WORK. It is not by any means generally known what a quantity of labour has been for some time past, and is now, employed on constructive work in connection with the Tamar-street Bridge. The extent and substantial character of the operations in situ are apparent to every casual observer who passes over the temporary structure which now spans the North Esk River, but what is going on at the foundry of Messrs. Bogle and Clark, in William Street, is a sort of sealed book to the majority of people. And yet it is here that the bulk of the constructive work is being steadily pushed ahead. Here the bridge is being literally manufactured.

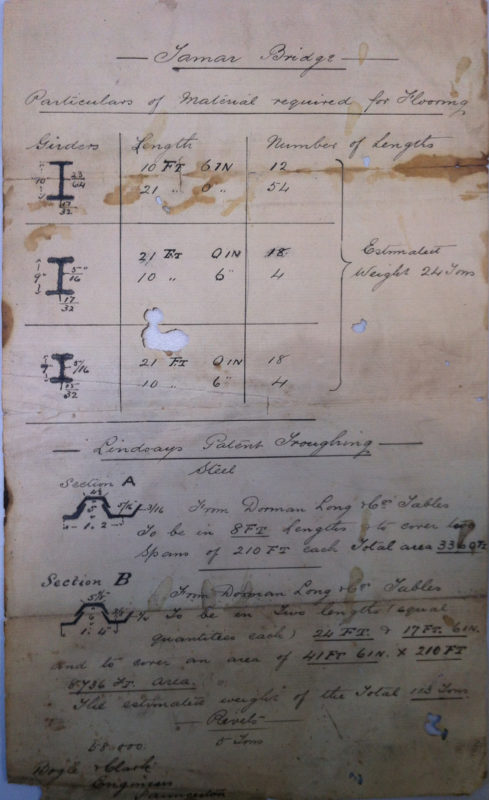

There is an impression abroad that many of the component parts of the structure are being imported ready-made, but this is far from the case. The crude material is, of course, procured from the old country, and the last shipment has just come to hand in the Eden Holme, but it is all being manufactured on the spot. In fact, an "Examiner" reporter who was shown through the shops and initiated into the exceedingly interesting mysteries of the iron founders' craft, was assured that three-fourths of the £12,000 vote is being expended in the colony, a fact which many, who might otherwise have been members of an army of unemployed, have to thank for constant and remunerative occupation. The iron and steel are imported, so is the cement, but all else, stone, timber, and labour, are Tasmanian. And what an amount of labour is required to produce the huge castings, the massive girders, the bed-plates, cantilevers, railings, panels, and a score ,of other smaller, but still indispensable, adjuncts to a well and truly constructed bridge.

Looking round, one sees girders in all stages. Here is one finished, here another and creditable specimens they are; there are others under way, some well advanced, some only ,in the incipient stages of measurement that precede the attentions of the punching machine. Hard by, one notices, just completed, a five ton travelling crane, and enquiry elicits the information that it was built to the order of the Tasmania G.M. Company for use in connection with the new pumping plant. It is a fine piece of work. But to return to the bridge. All round are to be seen minor portions of the structure in various stages of progress, bed plates, cantilevers, iron decking, guttering, panels, and the handsome railing which will border the footways. As giving some idea of the number of the various parts, it may be stated that there are in all 78 girders to be constructed, 18 of these being principals, and 60 intermediate. When, therefore, one comes to reckon up the infinite number of smaller parts, the magnitude of the task is apparent; and that it is all being done by a city firm, coupled with the thought that if Messrs. Bogle and Clark had not secured the contract another local foundry would doubtless have done so, points significantly to the eminently satisfactory conclusion that whatever iron work is required for our mines or other industries, can be faithfully manufactured in the colony, and probably with more expedition than would be the case had orders to be sent across the seas.

Certainly the Tamar-street Bridge promises to prove a good advertisement for the Tasmanian iron foundry business. It was stated in a recent issue of the "Examiner" that the power provided for screwing down the piles had been found insufficient, and conspicuous object in Messrs. Bogle and Clark's pattern shop just now is the outline of a worm wheel which is to be made, and which, it is anticipated, will about quadruple the available power. When this has been accomplished, the work of putting down the iron piles will be resumed, and this will enable this portion of the casting operations to be completed. The piles already cast are in 9ft. sections, two of which, together with the webbed section which is 4ft. 3in., are bolted together and first put down, the remaining sections being added one by one. When the piles are all sunk to the standard of stability, each will require an addition of a section of varying length to bring all to a uniform level, prior to the placing in position of the substantially capped section, in which the main girders will find their resting place. Until the requisite measurement, then, of each of these varying sections has been ascertained, the pile casting cannot be completed. The tour round the foundry was full of interest and instruction, and tended to impress the visitor with the importance to the city of this branch of industry. There was an evidence of healthy activity all through. In particular it was plainly to be seen how closely identified are the mining and iron founding interests, a couple of things that were responsible for this impression being the crane already mentioned and a very substantial casting for a "Universal" nozzle for use on the Briseis tin mine, and which was a splendid piece of work, and so constructed as to direct a jet in any direction desired. But these were only a couple of things among many which attracted attention, all of which contributed something to increase one's faith in the value of such an industry to the city in particular, and, the colony at large.

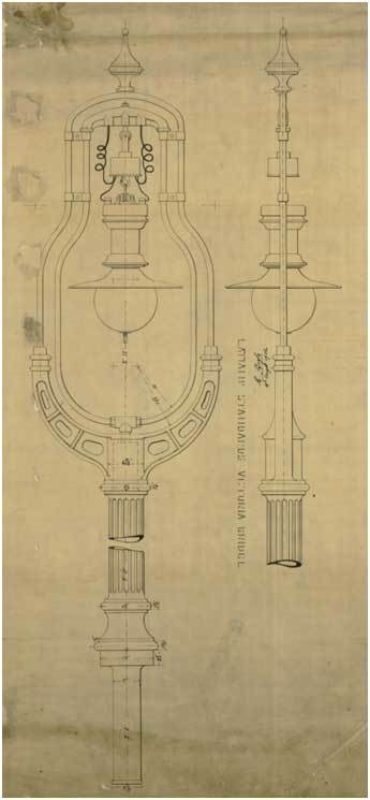

In August 1906,

Glasgow Engineering upgraded the old gas lamps on the Victoria Bridge to new

electric lamps. Designed by Edwin Bogle these were cast and manufactured at the

works. With Bogles qualifications as an electrical engineer, the company at

this time were undertaking wiring of houses and winding of electric motors and

all classes of electrical work. It is

interesting to note that Duck Reach Power Station was the first

publicly owned hydro-electric plant in the Southern Hemisphere, and provided Launceston

with hydro-electric power from its construction in 1895 to its closure in 1955.

Originally the installation had a capacity of 75 kW DC, provided by five

15 kW dynamos, and 360 kW AC, provided by three 120 kW

alternators. The turbines were manufactured by Gilbert Gilkes and Co., whilst

the dynamos and alternators were built by Siemens and Co. All

alternating-current (AC) supply was single-phase. By 1906 demand had risen and

it became necessary to upgrade the plant. This was done by removing much of the

original equipment and replacing it with four 445 hp Francis turbines

manufactured by Kolben and Co. of Prague, each coupled to a single 300 kW

three-phase alternator again built by Siemens and Co.. This raised the AC

capacity of the station to 1.2 MW. The original DC equipment remained in

use.

It is sad to note that this beautiful cast iron bridge was eventually dismantled due to a lack of maintenance in 1964. The Launceston Marine Board and the State Government agreed to build a new concrete bridge in its place which was opened in 1966. George Clark the last surviving member of the original crew who had built the bridge for Bogle and Clark and who had cast the hand rails for the 1899 bridge, helped unveil the new plaque. The Launceston City Coat of Arms plaques that were mounted on the abutment of the bridge now on reside on the front steps of the Town Hall.