Propeller Shaft Seals

Did you know that Glasgow Engineering sell all types of shaft seals, from the traditional packing style which we manufacture in house, to the PSS mechanical shaft seal.

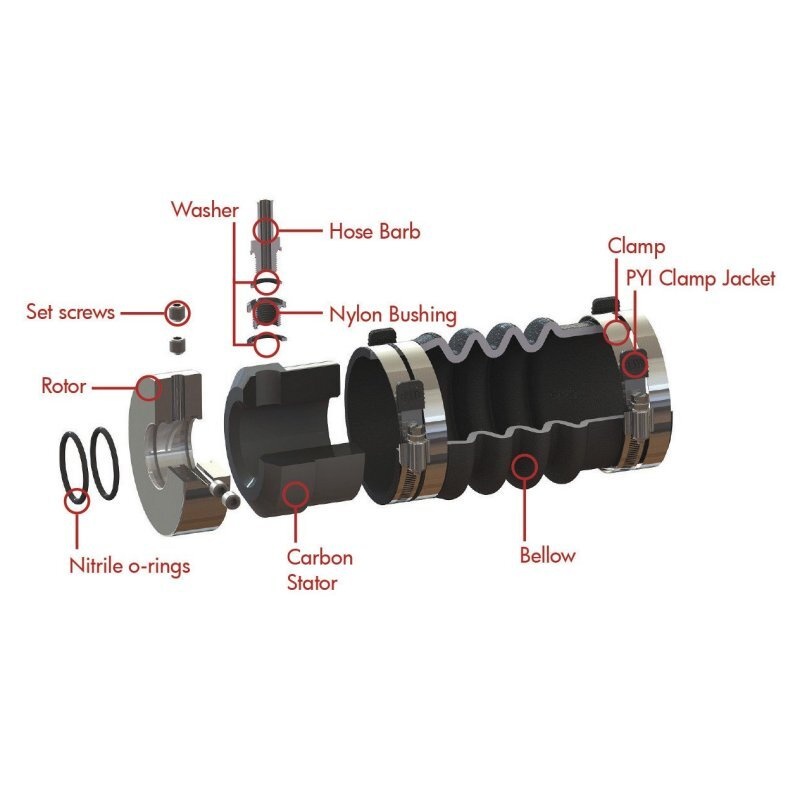

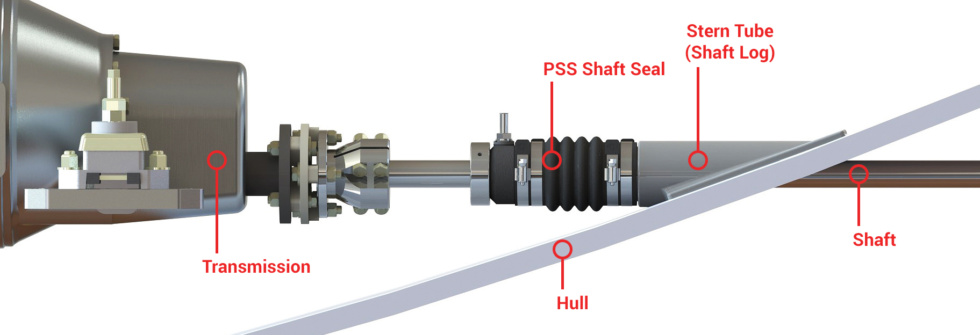

The most popular seal we sell today would be the Type A PSS Shaft Seal which fits shafts from 3/4" to 3-3/4" in diameter, used in most small pleasure craft and yachts around Northern Tasmania. The sealing surface is created between the flat surfaces of the rotating stainless-steel rotor and the stationary carbon flange. The stationary carbon flange is attached to the front side of the bellow with hose clamps, and the back end of the bellow fits over the Stern tube and is secured with hose clamps. The stainless-steel rotor is fit on the shaft in front of the carbon flange. The stainless-steel rotor is used to compress the bellow before the rotor is secured to the shaft with set-screws. This compression (pre-load) maintains constant contact between the two flat faces of the stainless-steel rotor and carbon flange, allowing the PSS to compensate for the variable fore and aft movement due to propeller thrust. The carbon flange is over-bored to the shaft diameter allowing it to “float” around the shaft and thus compensate for most misalignment and vibration problems. The stainless-steel rotor is sealed to the shaft by two O-rings that are recessed into the bore of the collar. These O-rings rotate with the shaft and stainless-steel rotor and do not experience wear during operation.